Why we say “The Art of Sake”?

Sake brewing passes through complicated processes. The sake master (Toji) needs to take care of each point in a delicate manner. It requires high expertise and continuous carefulness all through the processes.

I try to explain to you the key points of such a complicated brewing. It may be interesting but maybe somehow lengthy for you. You don’t need to read it through if you don’t have time or are not interested in such details.

The summary and the most important thing to know is that such complication enables Toji to make up the premium sake’s delicate taste and flavor without leaning on a fortune called “great vintage,” but only on his expertise and technique.

On the other hand, it also means sake sometimes falls into a terrible quality if the brewer neglects such carefulness to save operation costs.

If you are new to Japanese sake and enter the world of beautiful sake’s art, we commend you to start with brands already known to have premium quality like SOTO or Dassai.

Lack of temperature management in international logistics often damages even sakes, which are considered great in Japan, their origin country. Still, these two brands are brought to you even in Western countries under their careful temperature control.

It will be a tragedy if you try a terrible sake at first and walk away from the potential valuable experience without knowing the real beauty of sake.

Anyway, if you have a little time and be interested in the venture of the sake world, continue to the following.

The Basics of Sake Brewing

By the way, what is so complicated, and how a Toji (sake master) manages it with his expertise and techniques?

The points we explained in our previous post are as the followings.

- Yeast ( microorganism) derive enzymes and take energy by resolving sugar with them. Yeast discharges alcohol (ethanol) and carbon dioxide. This is the basic process of alcohol fermentation.

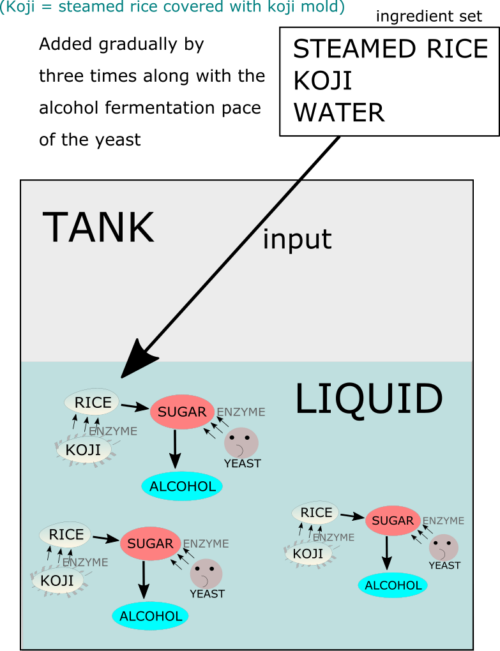

- In the case of Japanese Sake; They plant Koji mold on steamed rice. It is called “Koji,” and Koji’s enzymes will resolve the rice starch into sugar. In the same tank where this reaction happens, sake yeast will resolve this sugar and make the alcohol fermentation.

The actual works and phenomenon to reflect the above principle in the actual brewing is the following.

- To input the raw materials for the saccharification fermentation (fermentation to turn starches into sugars) (We call the following all together “ingredient set” hereafter.)

- WATER

- STEAMED RICE

- KOJI (STEAMED RICE COVERED WITH KOJI MOLD)

- The ingredient set turns the rice starch into sugar.

The sake yeast causes alcohol fermentation when it eats this sugar and derives alcohol (ethanol).

What are the challenges?

The subjects to handle in this procedure are live microorganisms. The reactions vary every time. Also, the two different lively responses will weave a far complicated and unforeseeable flow. Even the right set of brewing conditions will never guarantee the right product. Toji, the sake master, observe the liquid surface and add delicate adjustments in need based on his expertise and technique.

The things you should know to understand the sake brewing’s critical points

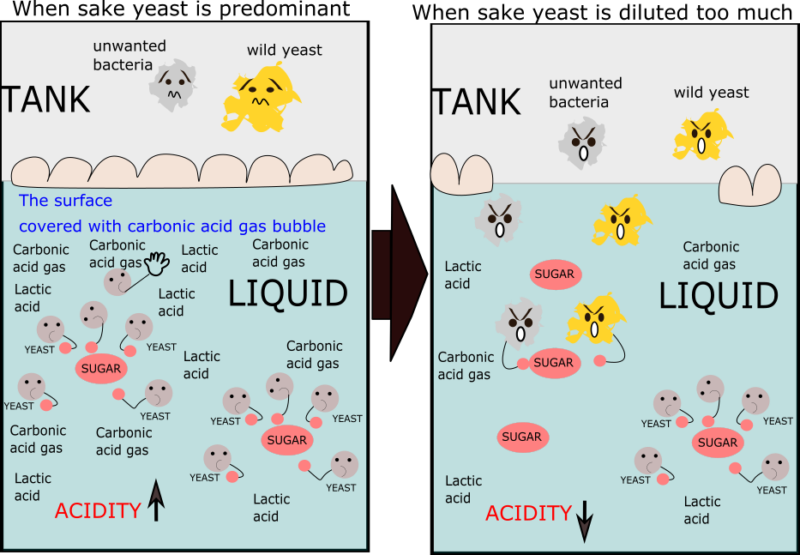

- The alcohol fermentation does not happen in a bio clean room. (Probably technically possible, but impractical in terms of the cost.) It means the liquid where the alcohol fermentation is ongoing always contact outside air, where numerous kinds of unwanted bacterias including wild yeast exist. The contamination can happen anytime.

- They nurture only the target microorganism, sake yeast, with the following methods.

- To make the environment where only sake-yeast can survive or keep its activity over other bacterias. Sake-yeast is endurable under high acidity and low temperature, where most of the others stop their activity and multiplication. (Once the sake yeast becomes predominant, it keeps its surrounding highly acidic on its own by deriving lactic acid and carbon dioxide.)

- To keep sake-yeast predominant. Besides its keeping the acidity, the predominant sake yeast will eat up the feed, sugar, and leave no room for survival for the other bacterias.

- To make the environment where only sake-yeast can survive or keep its activity over other bacterias. Sake-yeast is endurable under high acidity and low temperature, where most of the others stop their activity and multiplication. (Once the sake yeast becomes predominant, it keeps its surrounding highly acidic on its own by deriving lactic acid and carbon dioxide.)

The two critical control points to brew good sake

- As explained above, it is necessary to eliminate the room for unwanted miscellaneous bacterias and wild yeast for safety and to avoid unpleasant taste and flavor.

- Keeping the low temperature is not important only to prevent unwanted bacterias, but it keeps the alcohol fermentation active to the longest extent. A too rapid increase in alcohol will stop the yeast’s activity. The greater extent of the alcohol fermentation will resolve the rice starch as much as possible and make the taste of sake clean. It is also known that we can generate the premium sake flavor only in low-temperature fermentation.

What they actually do in their operations and managements

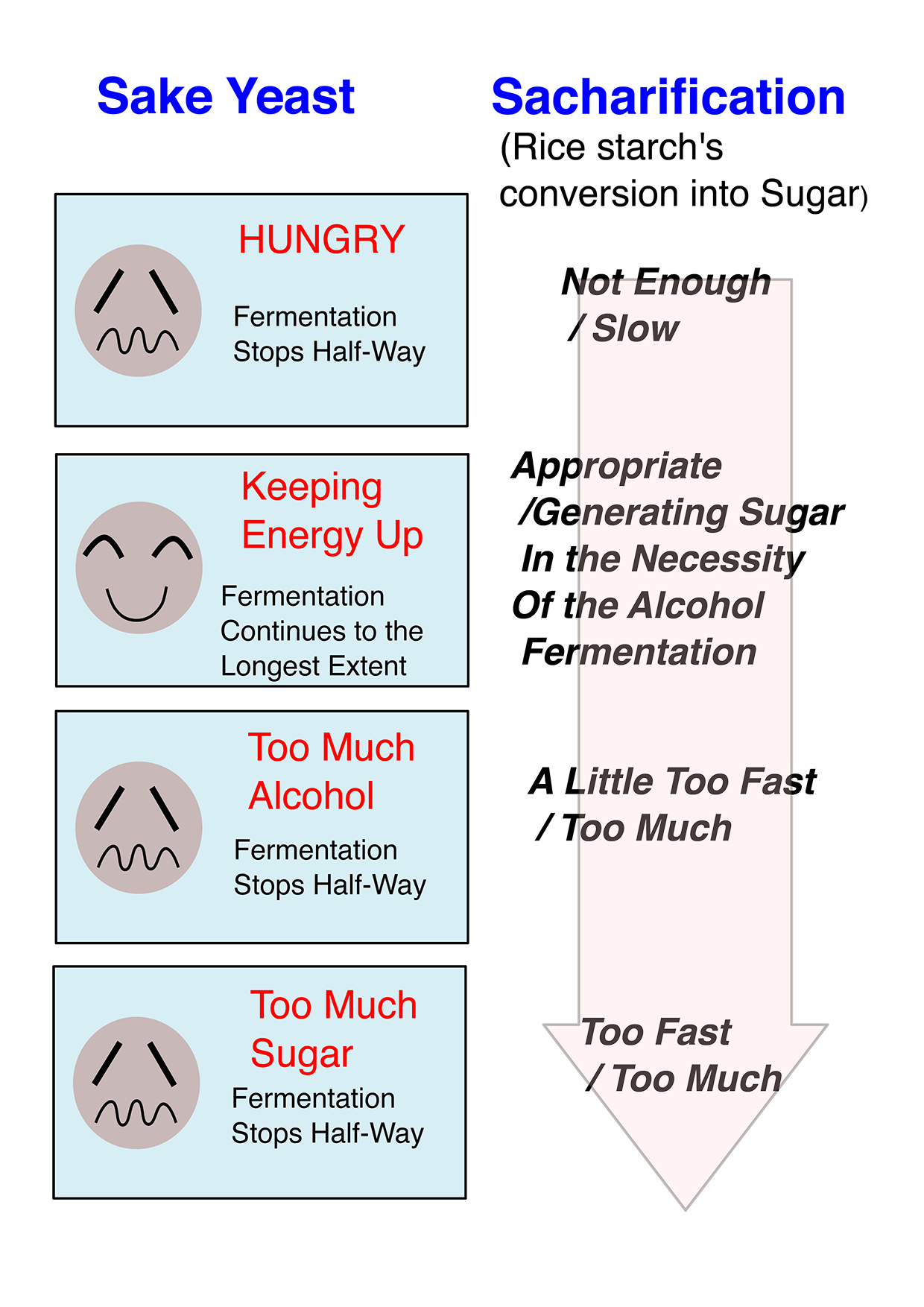

To implement the above conditions, the main thing that Toji, the sake master, does is to balance the saccharification (starch-to-sugar fermentation) and the alcohol fermentation in their speeds.

Multiple Factors To Complicate The Temperature Control

The following multiple factors always fluctuate, respectively, and change and require the best expertise of Toji, the brewing master.

- The initial temperature of the liquid in the tank

- The temperatures of the input steamed rice, water, and koji.

- Heat generation by the fermentation’s progress

- The alcohol fermentation will generate and increase the heat with its progression. It will make the temperature distribution uneven and hard to measure the temperature condition only with a thermometer.

Toji uses thermometers but makes his judgments at every critical point, eventually based on the traditional method. He finds what he should do by observing the liquid surface with full of his five senses.

Three Steps Input

As one of the principal methods, they input the ingredient set little by three times. It is called “three steps input.” When they input a portion of the ingredient set, it will dilute the yeast concentration and the tank’s acidity. Too much input will make them too low and give unwanted bacterias the room for multiplication.

Narrow Target of the saccharification speed / never too fast and never too slow.

They need to secure the right rice saccharification speed to keep up the yeast’s activity by providing enough sugar, the feed, on-demand. On the other hand, too much sugar by too fast saccharification will accelerate the yeast’s alcohol fermentation too much. It will make the alcohol percentage of the yeast’s surroundings too high and eventually prevent its own activity halfway. Otherwise, higher sugar concentration will also prevent the yeast’s activity.

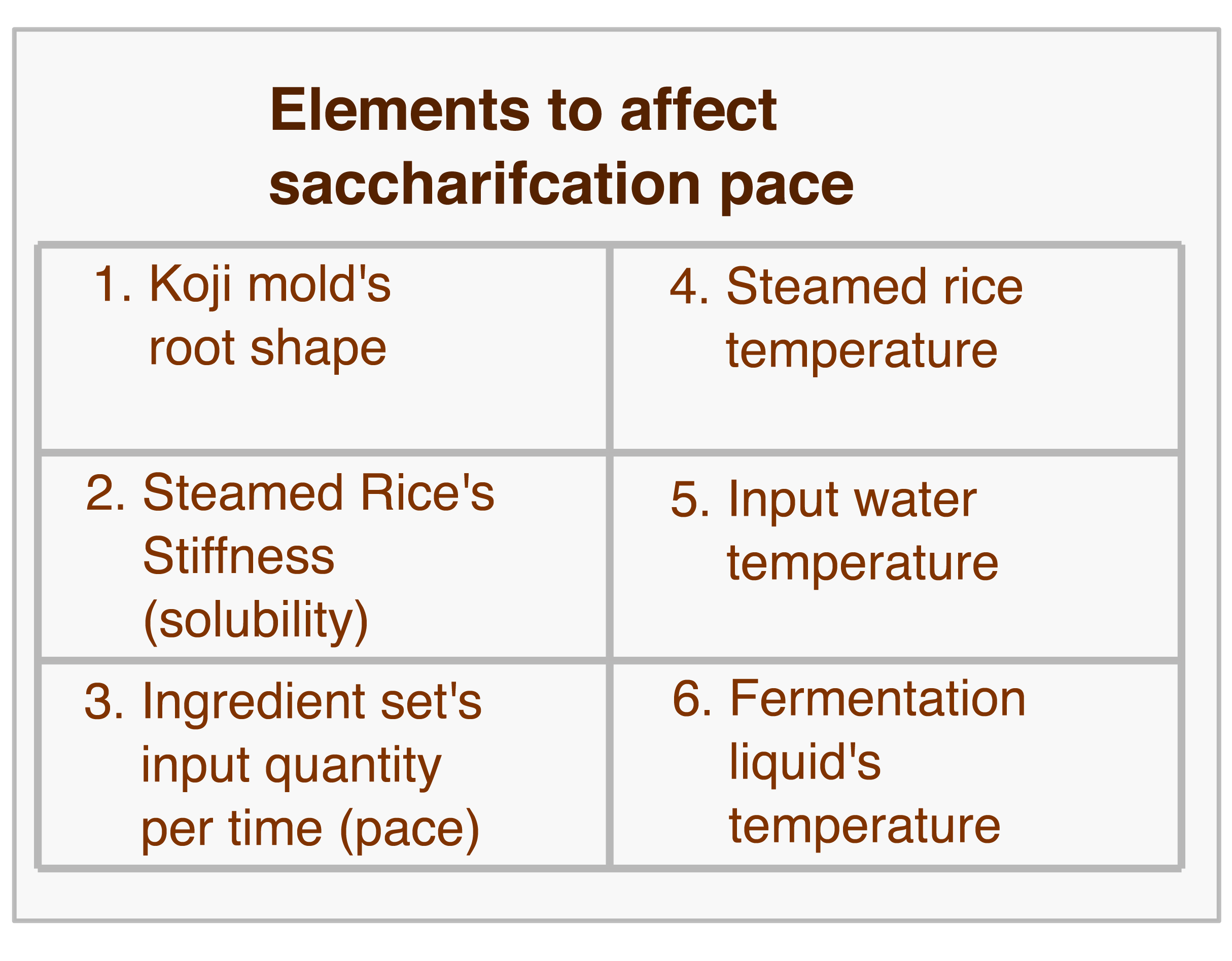

The followings are the major factors to affect the saccharification speed.

- The way Koji mold is rooted in steamed rice. The saccharification power is strong when it’s rooted deep inside the rice.

- Softness/stiffness of steamed rice (= moisture content). Both smooth melting and not-too-fast are required.

- Higher temperatures will encourage faster saccharification.

Such temperature control will directly affect the saccharification and the alcohol fermentation, as explained earlier.

Summery

Many other critical points affect the above matters in other processes like rice grinding, rice steaming, etc. They also require fine expertise in detail. We don’t write about them here, but you already know how sake brewing needs the expertise of sake masters and careful control.

In such a way, beautiful sake is made beautiful. Try a premium sake with such careful brewing and, don’t forget, shipped with careful temperature control.

P.S. How they make the yeast predominant at the start?

I explained that they need to keep up the high concentration of sake yeast in the fermentation tank. By the way, who do they start it? Do they purchase a liquid full of cultivated yeast? No. It was impossible in pre-modern while sake brewing procedure was already established.

The answer is that they do a similar fermentation in a tiny tank with a small volume before going to a big tank. This process’s main purpose is not alcohol fermentation (though it arises as a result) but the cultivation of the sake yeast. It’s much easier to control the environment in a small tank.

The sake yeast is not predominant here at the start. So they raise the acidity by lactic acid secreted by lactobacillus. The high acidity will prevent unwanted bacterias from multiplying, and the protected yeast increases. The sake yeast will generate alcohol through its multiplying (= alcohol fermentation). The heightened alcohol percentage will kill the lactobacillus, and eventually, only the sake yeast remains predominant.

This starting liquid is called “Shubo,” which means sake’s mother liquor. They carry the mother liquor into the main fermentation tank and add the ingredient set by the “3 steps input,” as explained above.